Float Switches

Multiple hanging floating switches that are activated as the fluid level within the tank rises and falls. The most common and economical way of controlling the pumps. Only provides a level signal. Multiple floats can provide multiple messages for example: high level, low level cut out, duty assist.

Submersible Pressure Transducer

This sensor sits at the bottom of the tank and measures the pressure, which converts to level control. This normally communicates with a PLC to control the pumps. They provide a reliable and flexible way of monitoring and controlling the pumps. Typically used where monitoring is in place or requires more information than a standard float system.

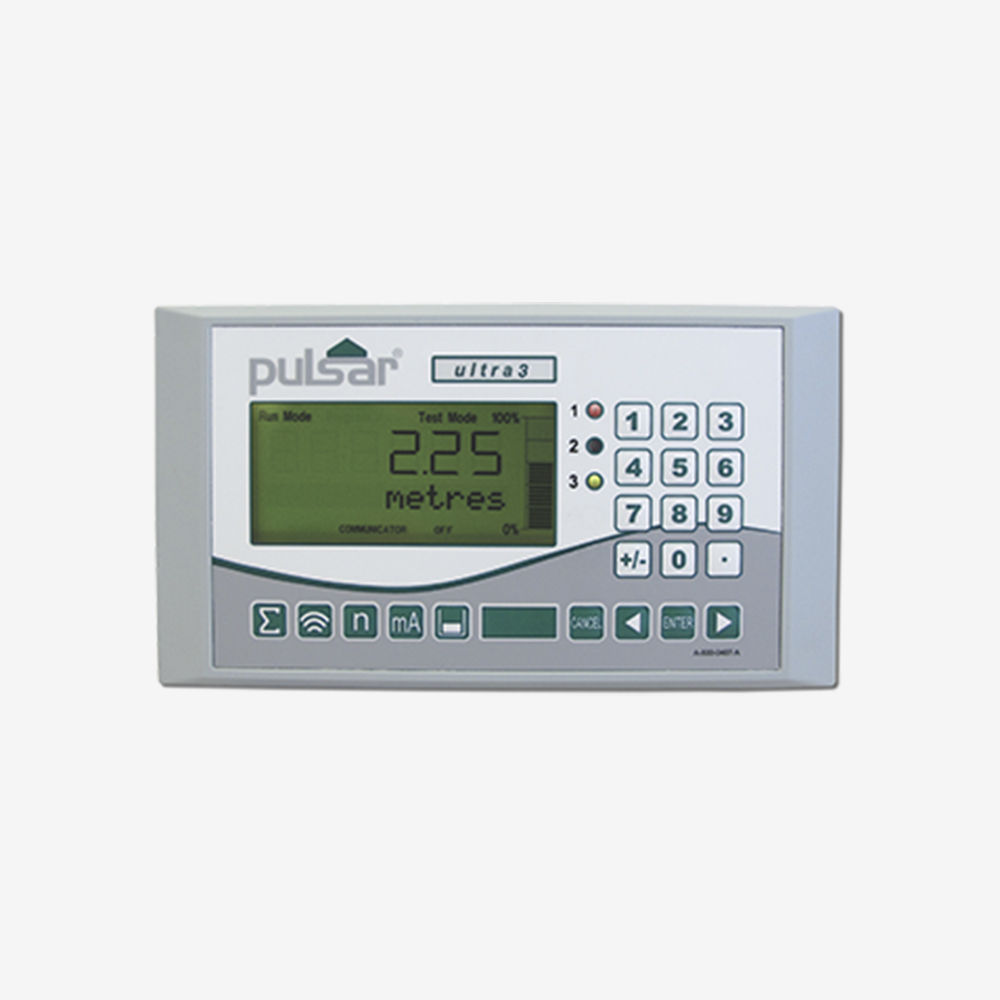

Ultrasonic Level Control

The ultimate level control method. A sensor at the top of the tank using ultrasonic waves to monitor the level of the fluid. As this does not come in contact with the fluid it is highly reliable. This system provides a digital read out of the levels. Used typically in adoptable pump stations, or where you have high turbulence within a tank in the fluid, or high fat content.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800