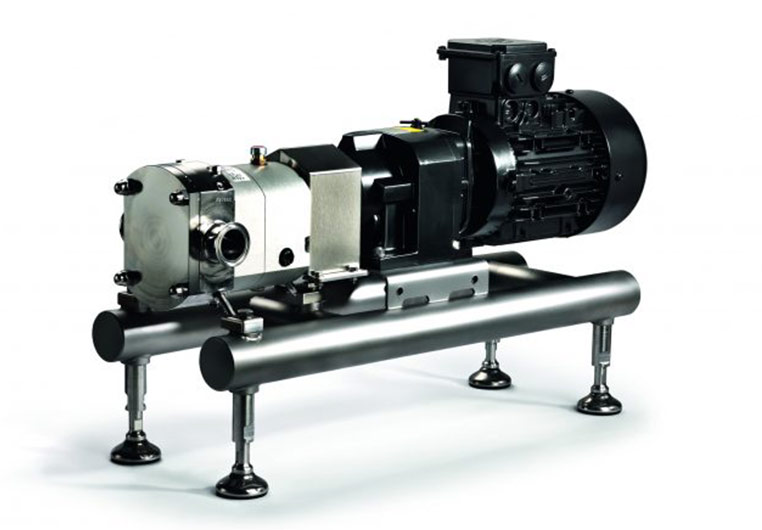

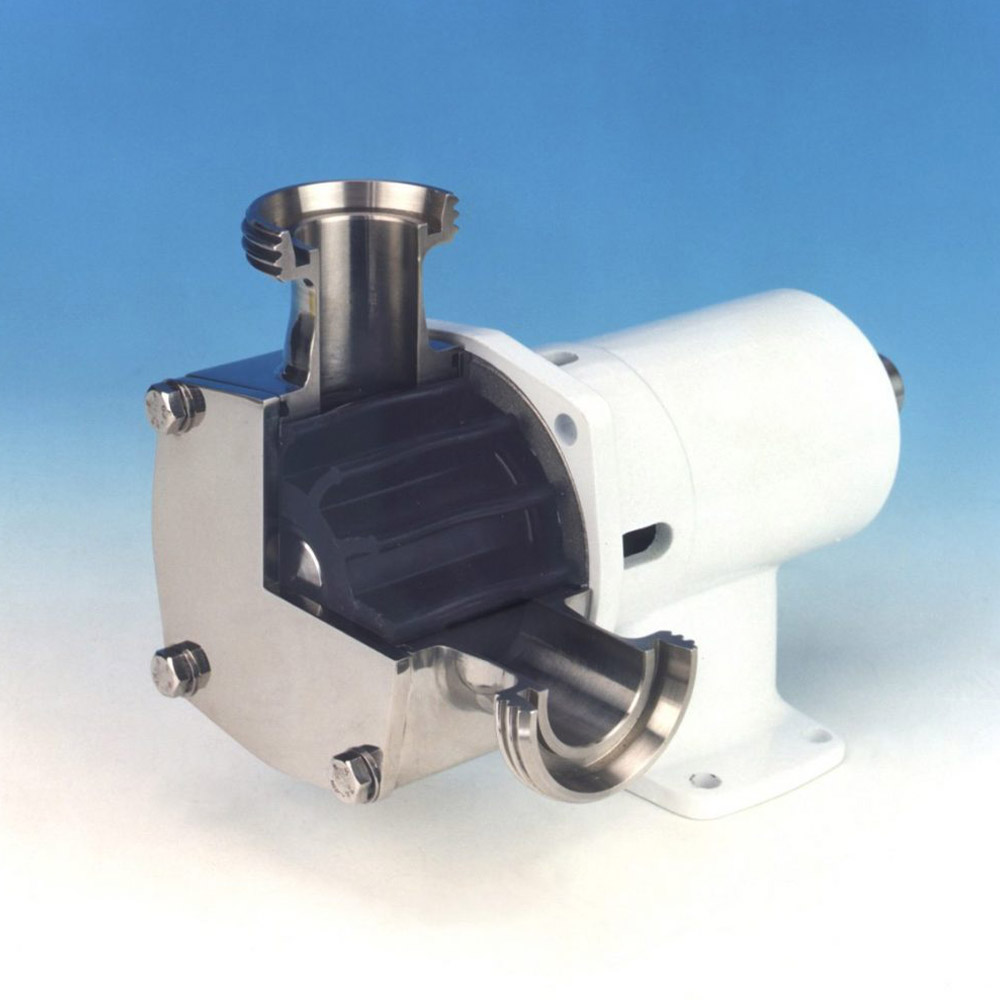

How does a flexible impeller pump work?

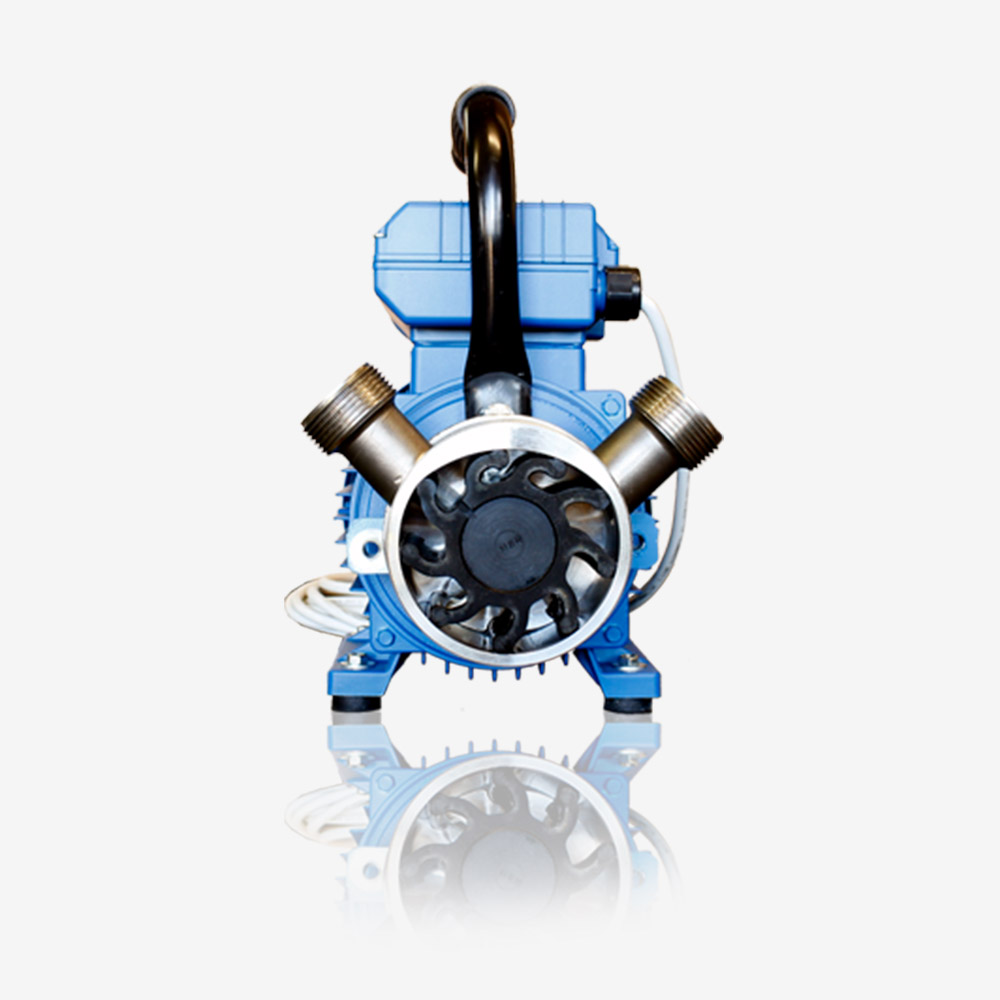

They are a type of positive displacement pump and are also known as flexible vane pumps. The flexible impeller works by a rotating rubber impeller with vanes that maintain contact with the pump inner walls. These vanes bend and then straighten as the impeller turns to conform to shape of the pump internal walls. This movement causes a vacuum which pushes the fluid round from the inlet to the discharge pipe.

Design benefits

- Variety of fluids – The impellers of flexible vane pumps are produced in various materials, making them compatible with a range of fluids. For example:

- Natural Rubber – For water based fluids

- Neoprene – Suitable for many chemicals. Can be food grade.

- Nitrile – Good for hydrocarbons and edible oils

- EPDM – Ideal for hot fluids and clean in place applications, acids and alkaline.

- Silicon – Used for temperatures up to 130 Deg C.

As the impellers are made of a supple, rubber type material that is able to bend, flexible vane pumps are also able to handle viscous fluids and those with high solid content without causing damage. Compared to other pumps able to handle solids in suspension, flexible impeller pumps are a relatively low cost solution. Excellent self-priming capabilities – Flexible impeller pumps are self-priming up to 6m from dry vacuum created by the rubber on the metal body. As a result, this pump design is popular in installations where a good suction lift capacity is required such as the removal of fluid from sumps and the stripping of tanks, drums and IBCs, without the need for a non-return valve or manual priming on installation.

Smooth, low pulsating flow – The working principle of the flexible vane pump benefits from a steady pumping mechanism that results in the flow output being a lot more consistent. The even flow rate makes it an ideal solution for filling, transfer and accurate dosing.

Reversible operation – Flexible impeller pumps are able to operate in either direction, which means that the pump itself can control the direction that the fluid moves.

Low shear operation – Flexible vane pumps are able to maintain their efficiency and priming ability even at low motor speeds. The low start up velocity of the operation as a result of the low RPM and gentle pumping mechanism means that shear sensitive fluids can be handled without any damage caused to their integrity.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800