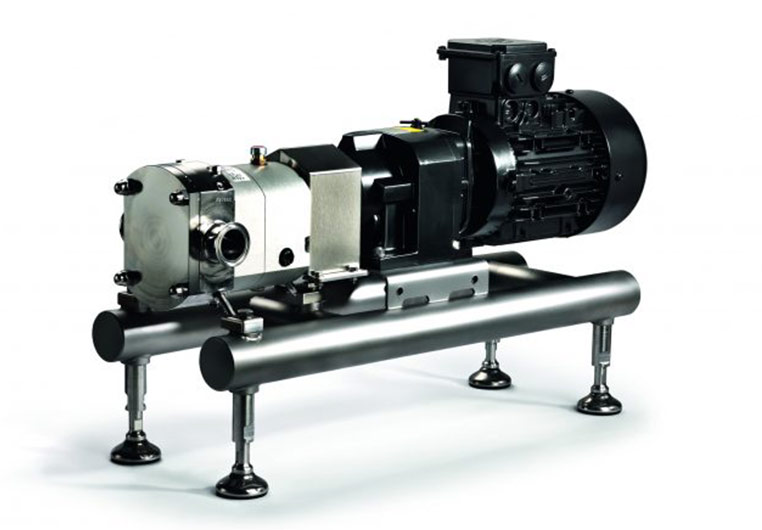

An air operated diaphragm pump (also referred to as an AODD pump) is a unique system that innovates by using compressed air as a source of power. This is achieved via a linked shaft which effectively shifts the compressed air from chamber to chamber, with both chambers able to move simultaneously.

This process of shifting compressed air from one chamber to the other forces liquid out of one chamber directly into the discharge piping. Meanwhile, the other chamber will be filled with liquid simultaneously.

Air operated diapragm pumps act by utilising reciprocating elastomeric diaphragms and check valves which effectively pump the fluid. Available with ball check valves or flat-type check valves, these systems are ideal for working with products that require sensitive handling.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800