How to make sure your pumps survive the winter

Posted on 30th September, 2020 by Dura Pump

Posted on 30th September, 2020 by Dura Pump

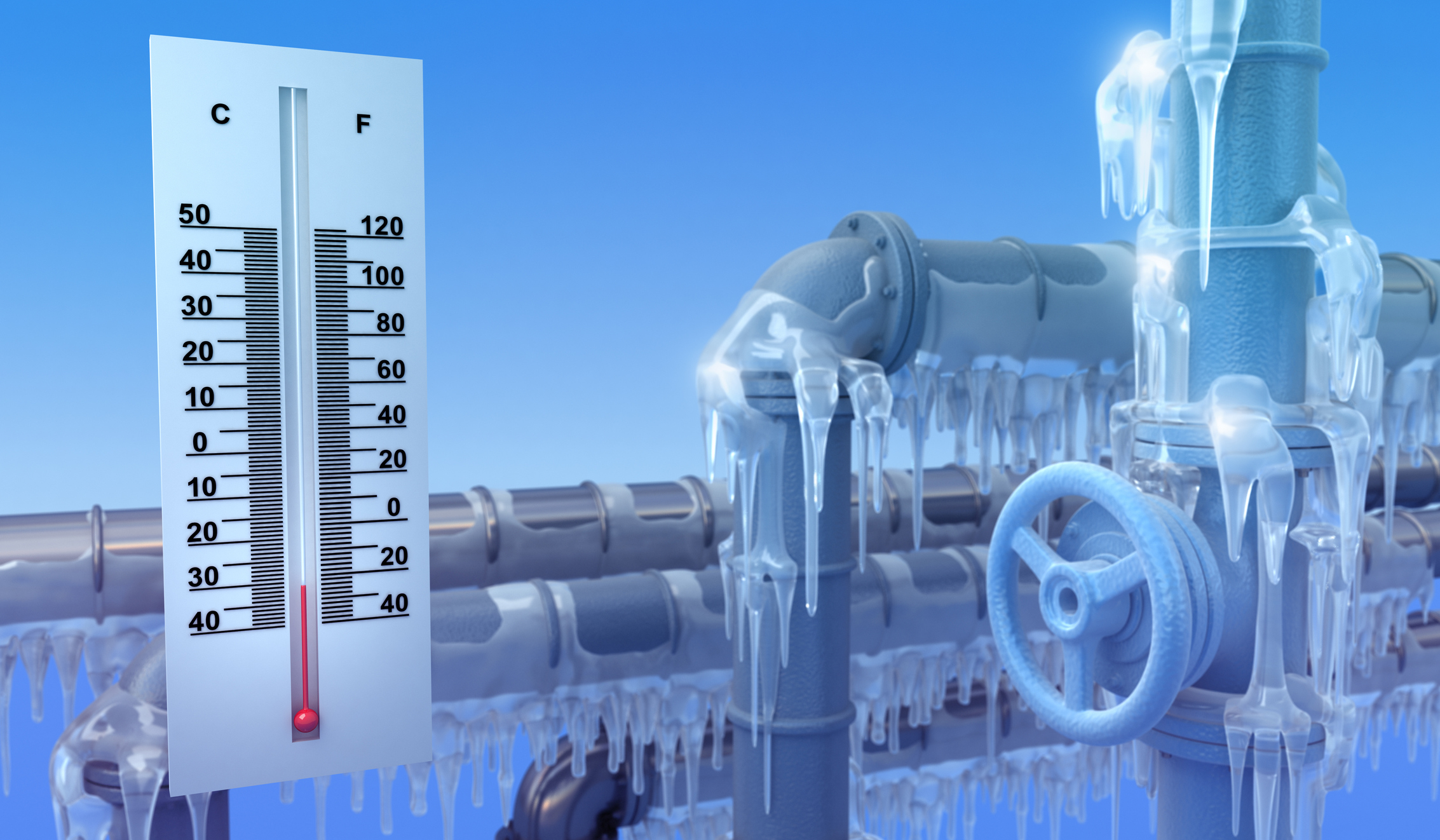

As the temperature starts to drop and winter sets in, it’s time to start thinking about preparing your pumps for the upcoming months. By preparing your pumps for winter, you will be reducing the risk of unnecessary hassle and possibly hefty expenses.

Pump seizure, burst pipes and component damage are all likely in the colder months if a pump isn’t properly maintained and in a worst-case scenario, catastrophic failure could occur.

The Dura Pump team are here to make sure you don’t get caught out in the cold. Follow the checklist now to help your pumps survive the winter!

AVOID COSTLY BREAKDOWNS MID-WINTER BY PREPARING NOW

Check the pump is free and not seized up

On some pumps, you can turn the fan by hand. If this is the case, move the fan on your pump system slowly by hand. This method helps prevent seal failure in the event of partial seizure.

Bleed the system to check no air is inside the pump

Trapped air in a pump will reduce the rate at which liquid flows through the pump and has the potential to greatly reduce the capability of the system. Make sure to bleed your system, to ensure there is no air trapped inside.

Check any associated filters (if fitted) are clean

Keeping an eye on any associated filters connected to your pump will help reduce the risk of blockages and ensure the system is moving smoothly. Dependent on the application of a pump system, winter can lead to higher volumes that need to be pumped. Regular cleans will help keep a pump in good service and will help monitor any recurring issues.

HAVING ISSUES WITH YOUR PUMP SYSTEM? CALL DURA PUMP NOW

Ensure isolation valves are open

We recommend all gate valves are opened fully, then turned back one-half turn to prevent seizure. Pump seizure can prevent pump operation completely, leading to costly downtimes and lots of other issues.

Check expansion bellows

Expansion bellows are a key part of a pump system for ensuring the process works effectively. It’s important to check on them and ensure the following are true:

– Fixing bolts are tight

– The rubber has not perished/is not perishing

Test run pumps

There should be no leaks from the pump. If there is a small weep, leave the pump to run for a short period, to give it time to bed back in. If the leak continues, contact our office to discuss what further actions should be taken.

The pump should run smoothly and without excessive noise. If the noise is coming from the impeller end of the pump, leave it to run for a short period as a build-up of scale may have formed.

EXCESSIVE NOISE FROM THE MOTOR END? CONTACT OUR TEAM NOW

Check controls and inverters (where fitted) for any fault codes

Some fault codes may require a simple reset, whilst others require engineer attention. Refer to the manufacturer’s manual or contact our technical support team for advice.

Is the demand on your system still the same?

Is your system optimised? Do you seem to be using more energy than you’re used to?

COMPLETE OUR ENERGY SAVING CHECKLIST

If you are worried about any of your systems this winter or would like a FREE energy saving survey, don’t hesitate to contact our experienced team today. Prevent issues before they happen, choose Dura Pump.