The Challenge

Slaughter and May required that the leaking cold water storage tanks in their London office be repaired and re-lined. As the water in these tanks is used for drinking, a suitable solvent-free solution had to be sourced.

The Solution

Dura Pump project managed this complex project and sourced suitable relining material from an industry-leading sustainable building solutions provider that offers water tank relining materials.

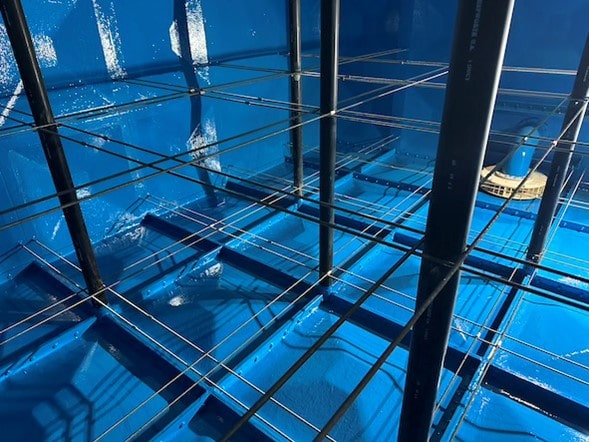

The full scope of the project was to re-line two cold water storage tanks, together, both tanks hold over 140,000 litres of water.

We re-lined both tanks to deliver long-term protection by applying suitable coating. The work was carried out one tank at a time to avoid disruption to Slaughter and May colleagues and customers.

The product used was a solvent-free drinking water polyurethane which offers numerous economic, technical and environmental features and benefits.

We delivered a repaired and re-lined solution with a ten-year guarantee to our customer with minimal disruption to daily activities.

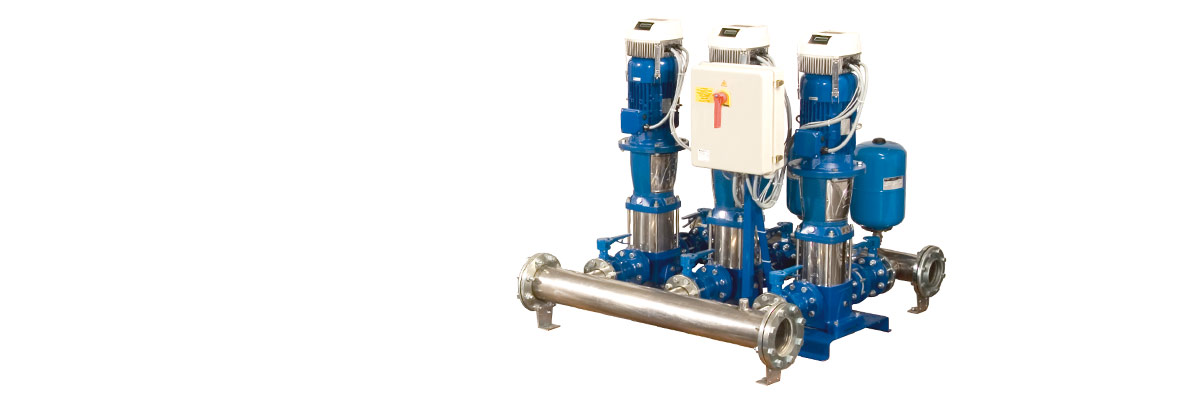

Dura pump also fitted two new valves with flange kits, bolts and gaskets to the fire tank pump. These are critical safety devices designed to isolate flammable liquids and gases from extreme heat and open flames.

Outcome

A compliant and safe drinking water solution was delivered which will provide long term performance with low maintenance.

Key Points

- The solution used delivers long-life performance with minimal maintenance.

- The ceramic tile-like finish means the tanks will be easy to clean. Critical for drinking water tanks.

- Phased implementation delivered to minimise disruption to the customer.

Ryan Damper

Project ManagerCase Studies