The Challenge

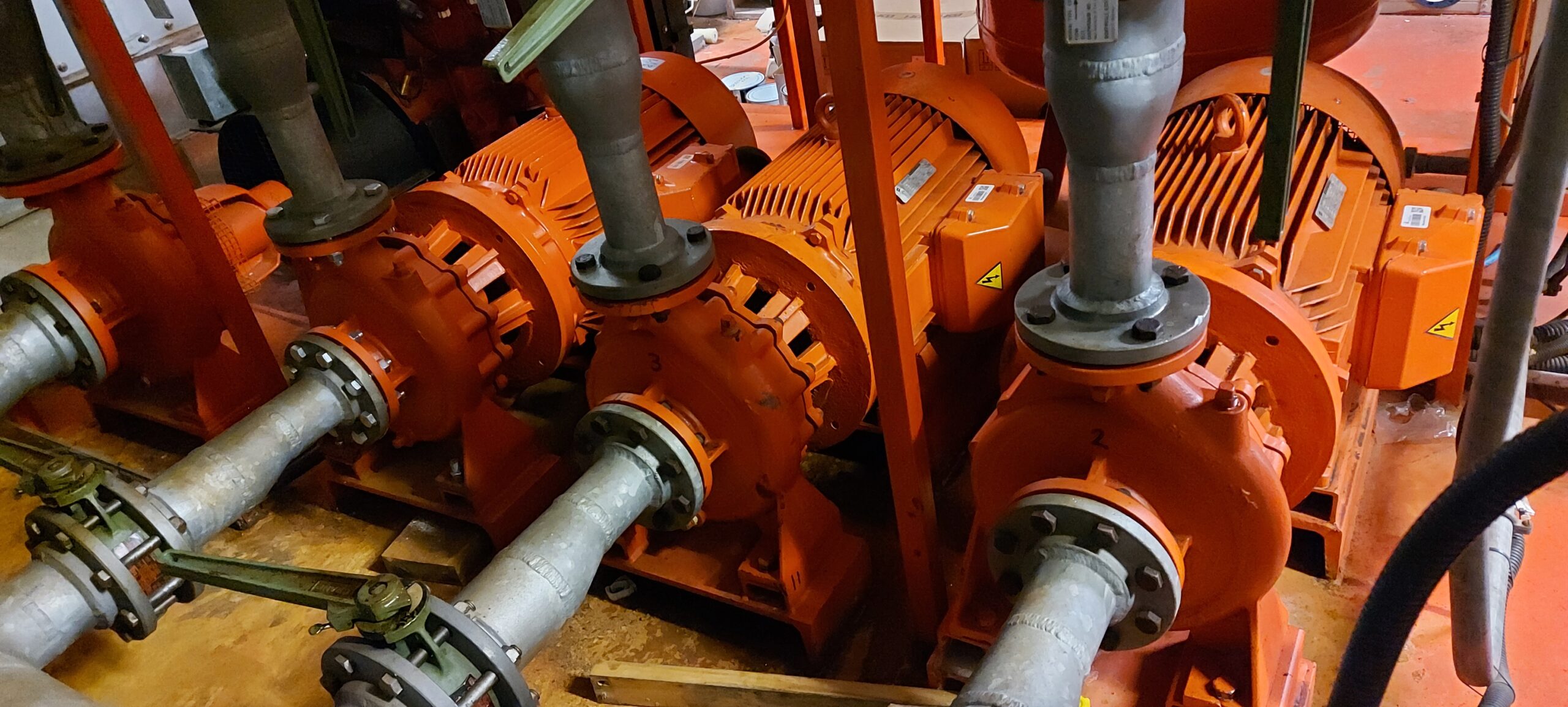

A food manufacturing plant required a pump to transfer various food products containing small particles into a filtration plant. The style of process at the plant meant that there was a possibility that a pump could run dry.

Our Solution

We identified that the best solution for handling the product and meeting the run-dry capabilities would be a diaphragm pump. A simple solution in this application is a standard air-operated diaphragm pump. However, the factory had no compressed air supply available.

We identified the Graco range of electric diaphragm pumps with an inbuilt compressor. Not only did this meet the needs for handling the product, but it also met the run-dry capabilities and was highly energy efficient compared to a traditional air-operated unit.

The Results

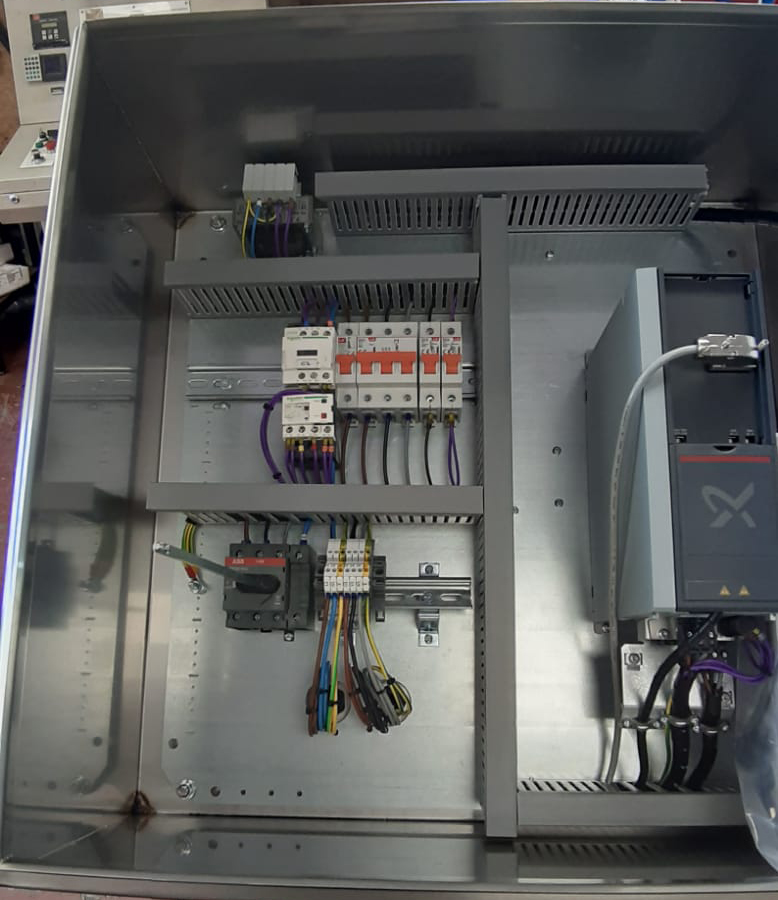

The pump was mounted to a stainless steel skid unit with the control system and delivered to site ready for use.

The result was a great solution that met all of the manufacturer’s requirements of product handling and run-dry capabilities; with the added benefit of very low air consumption required. The pump has all the characteristics of an air-operated diaphragm pump, such as good suction lift capabilities and the ability to stall if operating against a closed valve. These pumps are manufactured in a wide range of materials including food-grade materials and hygienic. They have a highly controllable flow rate due to the inverter controlled drive which makes them highly energy-efficient when compared to an air-operated unit.

Case Studies