The Challenge

A London Hospital, operating independently, collaborated with Dura Pump to explore avenues for energy savings. Our dedicated team conducted a comprehensive energy savings survey to pinpoint opportunities for enhancing pump efficiency and subsequently reducing the hospital’s energy expenses. Following the audit, we identified three sets of pumps that offered the most promising return on investment. To illustrate one such option, we focused on a pump requiring replacement within the CT system.

The specific pumps in question were Pullen pumps, utilising an 11kW motor driven by a belt. Recognising that belt-drive pumps operate at a maximum efficiency of 80% due to losses through the belt, we realised a substantial reduction in kW size was achievable by transitioning to new direct-drive, high-efficiency pumps.

Proposed Solution

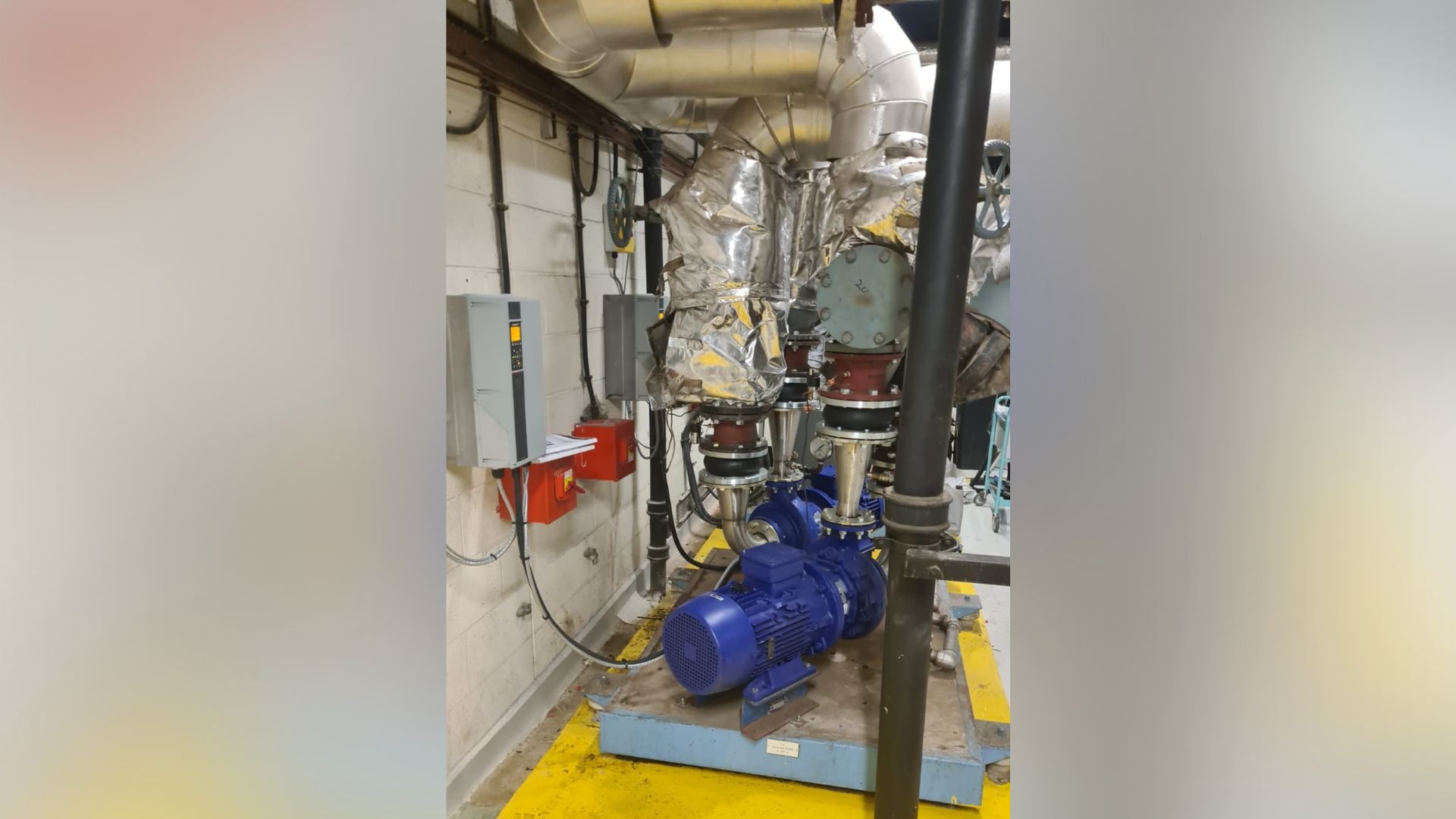

Our technical experts recommended a KSB Etabloc, direct-drive 5.5kW pump, precisely matching the existing duty but with motors half the size. Our estimation team compiled a comprehensive package covering supply and installation, encompassing pipework modifications and electrical connections.

Upon completion, we determined that the payback period was only 1.18 years, resulting in a savings of 43,362 kWh. At the customer’s electricity rate of 44p/kWh, this translated to a first-year savings of £19,079. With the customer’s approval, we proceeded to supply and install the system, ensuring a reliable solution for years to come and delivering significant energy savings throughout the pump’s lifespan.

Outcome

Consequently, the customer benefited from reliable pumps, reduced energy costs, and contributed to their net zero targets, aligning with environmental sustainability goals. This achievement marked a comprehensive win-win situation.

If this sounds intriguing, contact our team at 01604 648800 to explore whether you qualify for a complimentary energy audit.

Case Studies