The challenge

A world-renowned flooring manufacturer approached us with an urgent need. Its insurance company had condemned its old fill and spill system, and a replacement was critically important to its operations.

When it came to the replacement, the biggest issue was that it must allow for hot water pressurisation up to 195 deg C at 20 bar, as well as enabling the pressurisation of all the cold water in the factory.

Our solution

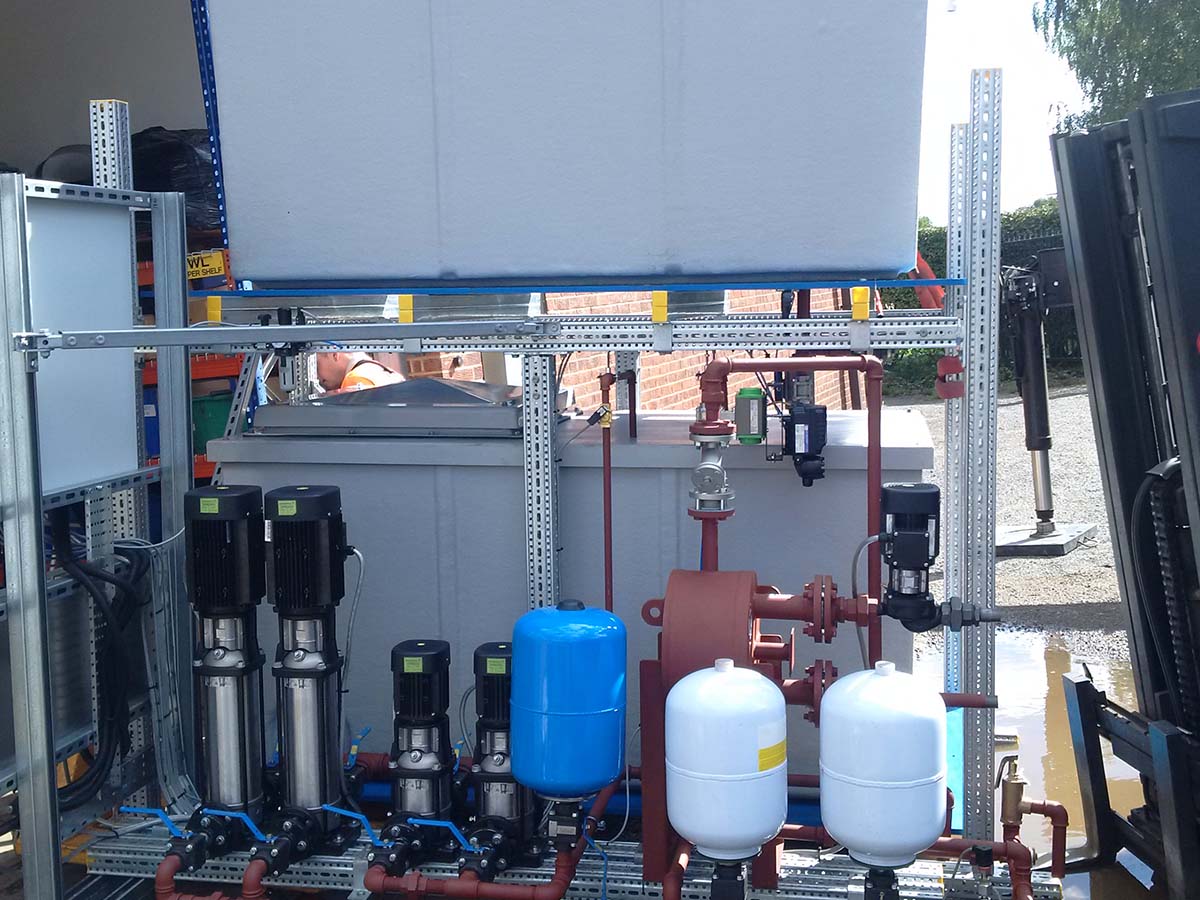

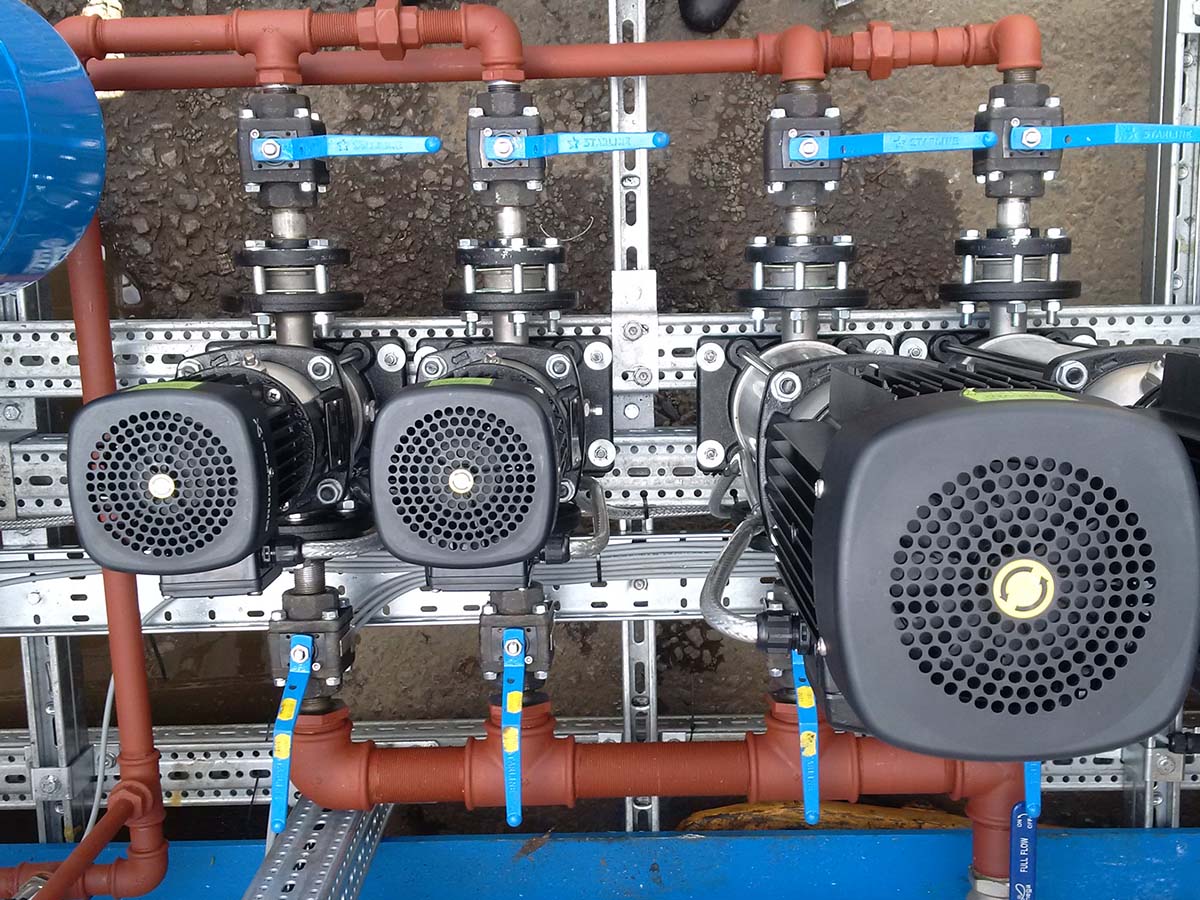

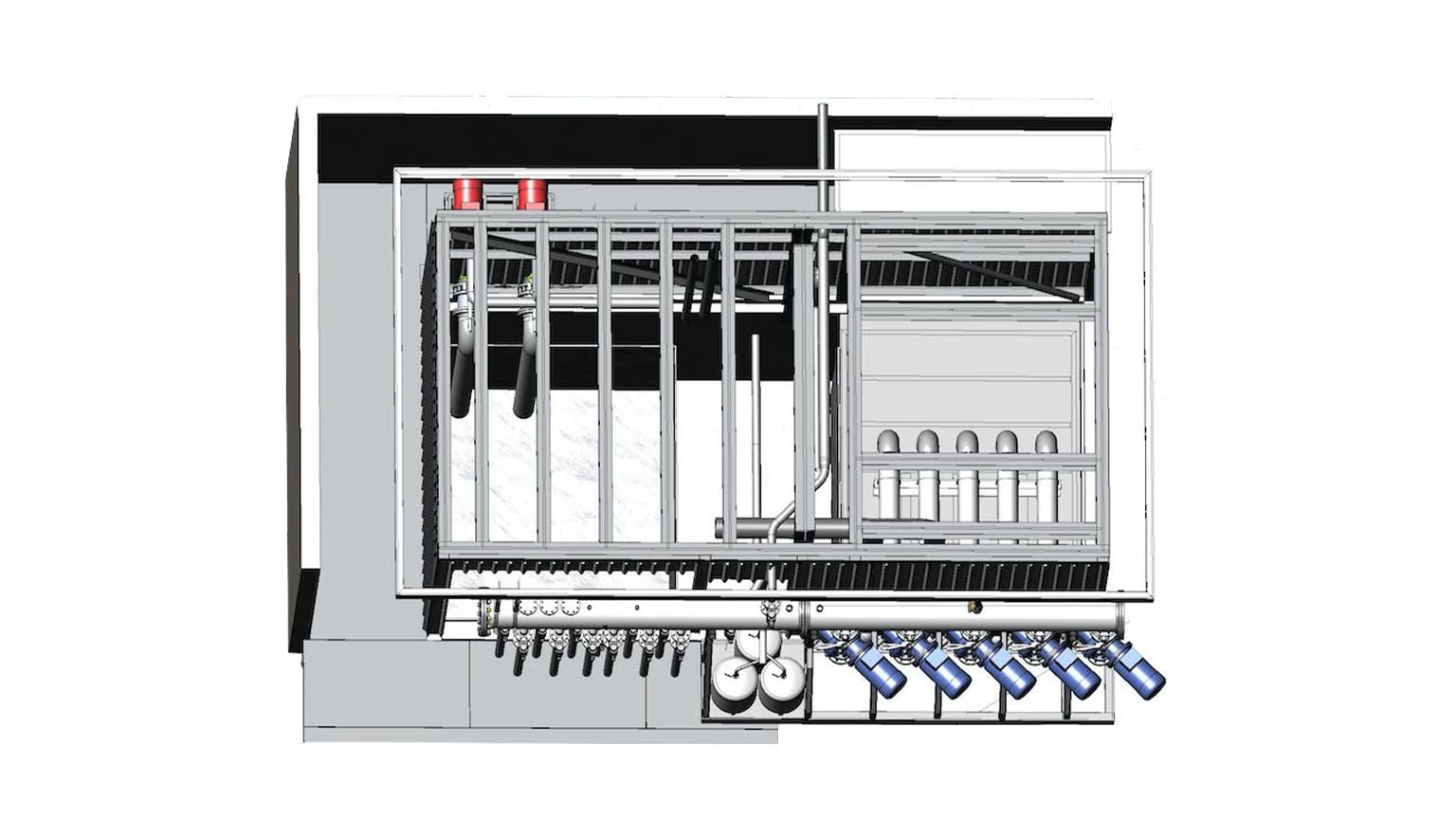

We designed, built and supplied an automated system on a single steel frame skid unit that controls the pressure in both the chilled and high-temperature hot water systems.

It incorporates a cold water header tank, a cold water system tank, four inverter-driven multistage pumps, a pressure control valve and three pressure valves.

Its sophisticated control panel has a colour touch-screen display, heat exchanger and pressure relief valves. To enable the control of the high pressure and the hot water, it has air-activated v-groove ball valves, inverter drives, pressure relief valves, temperature probes, pressure sensors and PLC.

The results

The flooring manufacturer’s insurance company has approved the new system, which they report has proved safe, reliable and simple-to-use. It requires minimal maintenance.

Related Case Studies