Are belt drive pumps really inefficient?

Posted on 27th November, 2017 by Dura Pump

Posted on 27th November, 2017 by Dura Pump

Belt Drive pumps, by design, are inherently inefficient.

Most belt drive pumps were installed in the 70s to 80s and haven’t been updated since, causing major problems with inefficiency. Did you know that a belt loses 20% of power regardless of the function it is performing?

Luckily, technology has moved on leaps and bounds in the past few decades, meaning there are ways of significantly improving the efficiency of your pump system.

The Dura Pump solution

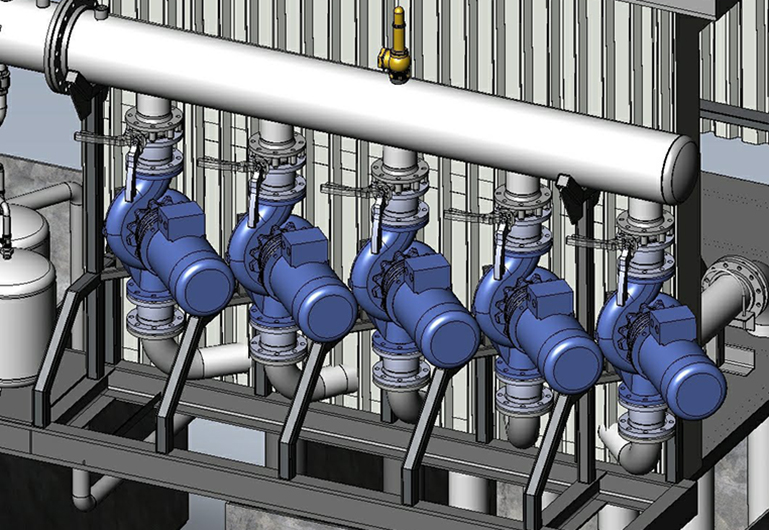

We recommend installing a direct drive pump which can save

30-40% of power in any application. In addition to saving a large amount of energy, you will encounter fewer maintenance costs and keep downtime to an absolute minimum.

Belt Drive vs. Direct Drive – what are the differences?

Belt Drive Pump:

- Has a pulley mounted to its solid shaft and is driven by one or more belts that are attached to a pulley on the motor or engine

- Pumps typically turn at 900-1400 RPM

- Loss of efficiency due to the additional friction from the belts and pulleys

- Maintenance required to adjust the belts

Direct Drive Pump:

- They have a hollow shaft which simply slides onto the drive shaft of a motor or engine

- Since the pump is connected directly to the motor/engine shaft, the pump RPM is the same as the motor/engine RPM – normal gasoline engine speed is about 3450 RPM

- Electric motors typically will turn a direct drive pump at 3450 RPM or 1725 RPM

- Compact design

- Lower maintenance requirements

We demonstrated the capability of switching to direct driven pumps in our work for Oracle, a world-leading software company, who were experiencing persistent issues with the heating system in their UK headquarters. After a survey of their current system, Dura Pump found that the primary cause of the issue was the old belt drive pumps being run on the heating system. These were malfunctioning frequently and running inefficiently even at the best of times.

We replaced their belt drive pumps with a newer, more modern direct driven centrifugal pump. These are not only more reliable, but also more energy and cost-efficient. The centrifugal pumps saved a huge 20% on energy use over the old belt drive pumps!