Chilled water or Chiller pumps, are one of the most widely used pump and are simple, effective and reliable. In a standard set up water enters the pump via a horizontal pipe, goes through the impeller and – using centrifugal force –is flung out a vertical discharge. These can be found with glanded or glandless motors, otherwise knowns as canned motors. Smaller canned inline pumps typically come as standard with motor mounted inverter drives Inline pumps are normally available in single or twin head, which can be configured to automatically swop duties.

These pumps are available in stainless steel for applications where chemical is present.

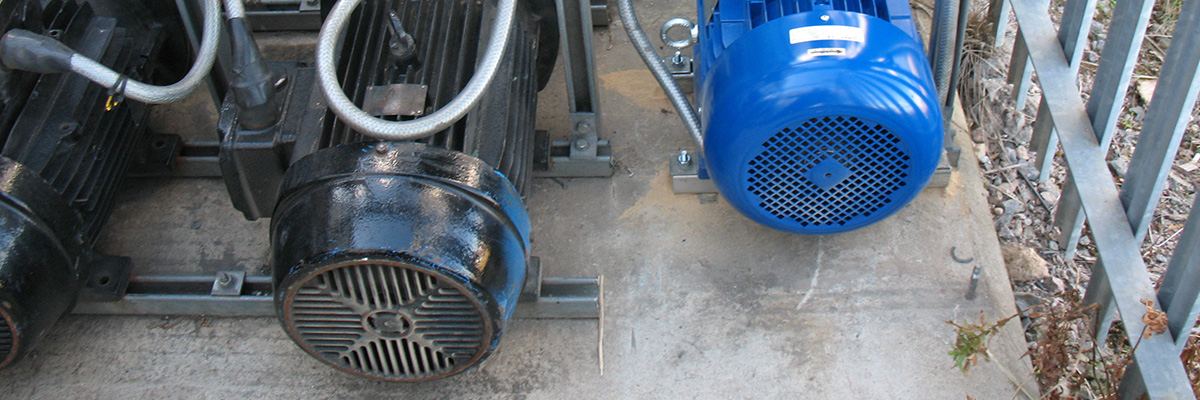

Chiller pumps are used to overcome the resistance in the pipework and valves or to lift the water out of the hot or cold well and push through the chiller unit, cooling tower or system for cooling Old belt drive and fixed speed systems can be easily upgraded to new energy efficient systems with payback times from 6 to 36 months, depending on application. In addition to saving energy, this can be a cost effective way of upgrading your system. Let your energy savings pay for your upgrade.

Solve your water pressure problems today, call 01604 648 800

Solve your water pressure problems today, call 01604 648 800