Challenge

A new client called us faced with a problem nobody wants: a failing sewage system. We attended the site and found some very old Mono progressive cavity pumps, SB munchers and level controls that were no longer fit for purpose. The system was tripping out and required a major overhaul.

The capacity of the site had reduced since it was first built, so it wouldn’t have proved economical to carry out a like for like replacement of the existing system. Instead, our team was challenged to provide an modernised pump system to handle the site’s current reduced demand, all whilst ensuring we provide a reliable solution that’s optimised to deliver high performance results.

Solution

Our solution was to upgrade the system to two free standing submersible grinder pumps in the tank of the pump station, both fitted with a new float level control.

This included:

– Provided a tanker to attend the site to clean and empty the existing tank

– Removed existing pumps, munchers, and panels from the plant room

– We made all electrical and mechanical connections, tested and commissioned the system

Supplied and installed:

– Two grinder submersible pumps

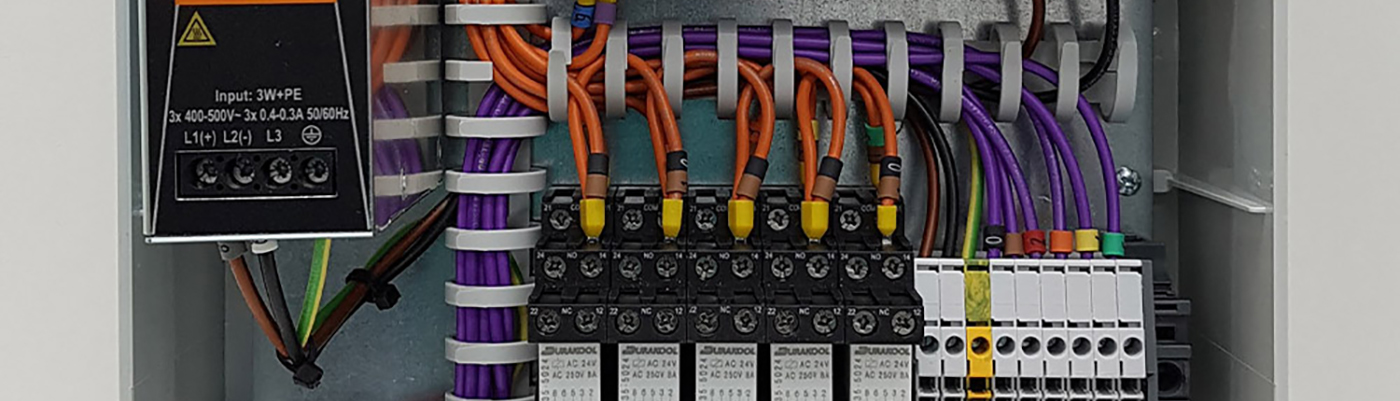

– Dual control panel

– Flexible pipework in the pit, leading up to cam locks and PVC pipework connecting onto the existing discharge pipework

– Gate valves and non-return valves

We also removed the existing suction pipework and utilised the concrete shaft out of the tank for safe accessibility during the project.

| Pump Station Before | Pump Station After |

|

|

| Control Panel Before | Control Panel After |

|

|

Result

As a result of our programme of works, our customer was able to take full advantage of a modern and upgraded system within their budgetary requirements without compromising on reliability. The finished result was a fully operational sewage system, resulting in a significant reduction in downtime and costly maintenance on site.

Case Studies